|

| June 17, 2014 | Volume 10 Issue 23 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Wheels:

Local Motors announces winners of first-ever 3D-printed car design challenge

Local Motors' Direct Digital Manufacturing (DDM) original electric car concept to be built at IMTS 2014. This concept will be modified and updated to include design ideas generated by the company's 3D-Printed Car Design Challenge.

Local Motors, a pioneer in the online design and hardware co-creation market and known for creating a really cool customizable car called the Rally Fighter, announced earlier this month the winners of its first 3D-Printed Car Design Challenge.

The company launched the contest in April to uncover concepts that could have potential to influence the design of the full-size Local Motors electric vehicle body that will be 3D printed live on the floor at the IMTS show in September. (Yup, you read that right. Printed on the show flow.)

Some winning conceptual elements demonstrated in the contest may be integrated into the 3D-printed car design to enhance build quality, process, functionality, and style.

More than 200 entries, representing submissions from 30+ countries around the globe, were submitted during the six-week challenge. After a week-long voting period and review of all entries by an independent panel of expert judges, a total of seven designs were selected as winning concepts.

Video: Local Motors' announcement of the winning entries in the 3D-Printed Car Design Challenge.

"We're printing the body and frame of the vehicle, along with seats and anything else that we can," says James Earle, advanced manufacturing engineer at Local Motors. ... The printed parts will all be one piece."

"We won't be printing the drive train components or any other electrical systems," says Earle.

Overall 3D-Printed Car Design Challenge winner

The winning concept, Strati, created by Michele Anoe of Italy, will highly inspire the full-size 3D-printed prototype. "It's simple and clean, with character," said challenge judge and MakerBot CEO Bre Pettis. "It has a nice style that really hangs together." Lonnie Love, Group Leader, Robotics and Manufacturing Systems Research at Oak Ridge National Laboratory, added, "Michele's design offers an excellent balance between innovation, complexity, and practicality. It has good 3D lines, and the retractable roof is really cool."

Michele will receive a $5,000 cash award for his submission and will be invited to see his concept manufactured live in AMT's Emerging Technology Center, Booth N-650, at the IMTS Show this September.

"There are three major challenges facing the auto industry today: part count, weight, and the initial cost of tooling when creating and iterating on vehicles. The hybrid Direct Digital Manufacturing process stands to address all three of these," said Jay Rogers, Local Motors CEO. "When these hurdles are removed, we open the door to an exciting new era in automotive design and manufacturing possibilities."

Six additional concepts were recognized for their innovation and popularity among the members of Local Motors' global community. The company is big into shared design via the Internet. Some aspects of these designs may also be incorporated into the final prototype. The designers of each of these concepts will receive a $1,000 cash award from Local Motors.

A favorite from the beginning, Internal Strut Frame has an innovative design that uses vertical struts to support the upper surfaces, saving weight and making a sturdy frame/body. This concept was selected as the "community favorite" by members of Local Motors' global community.

Also employing an innovative use of vertical structures to support external surfaces, catering to the inability of current 3D-printing process to bridge horizontal gaps, Aeroblade's multi-layer design was described as "very futuristic" by judge Douglas K. Woods, President, AMT - The Association For Manufacturing Technology. "This design really has the 'wow' factor, like something Batman or the Green Hornet would drive," Woods said.

Creative structural supports, including the spine down the center, and a clean passenger compartment are defining elements of the 3DPCX concept. In his judge's notes, Paul R. Warndorf, Vice President, Manufacturing Technology, AMT noted, "By incorporating simplicity and innovation via smart design and smart deployment of vehicle features, the 3DPCX brings the openness of the road inside the vehicle."

The LM Supernova incorporates interior design elements that are not only innovative and well thought out, but highly functional and lightweight. This is a great example of using good design and engineering to create a truly innovative vehicle. According to Woods, "The Supernova looks tough and fast, like a Formula 1 racecar."

The Mirage took an innovation award for incorporating layers to create 3D-printed "crumple zones," which is not only unique, but also very innovative. Taking into account how the technology could be used, the Mirage concept "is a great-looking car, offering some solid suggestions for what can be achieved with additive manufacturing," said Rick Neff, Manager, Market Development for Cincinnati Incorporated.

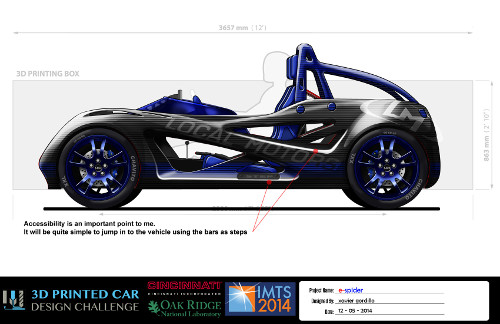

"A tribute to the minimalist in all of us, the e-Spider merges the efficiency of a smart car with the effectiveness of a desert dune buggy," said AMT's Warndorf. The e-Spider's roof design and windshield connections, as well as the incorporation of shielding accessories to allow for use in severe weather, showed a great combination of innovation and practicality.

Local Motors is also working with Cincinnati Inc., a metal fabrication juggernaut for more than 100 years, and the Department of Energy's Oak Ridge National Laboratory (ORNL) to develop and commercialize a new large-scale additive manufacturing system capable of printing huge polymer components -- much, much faster than many current systems can build small parts. You can read that exclusive Designfax article here.

Source: Local Motors

Published June 2014

Rate this article

View our terms of use and privacy policy